A well-trained maintenance staff makes the difference between years of trouble-free operation and years of increasing downtime.

For more details, please contact us:

Phone: (971) 264-0400

Hydraulic systems are critical elements in many industrial applications, including construction, manufacturing, and transportation. They are used to power a wide range of machinery, from excavators and cranes to aircraft and rockets. However, hydraulic systems can fail, and understanding the causes of hydraulic system failure is essential for those who work with these systems.

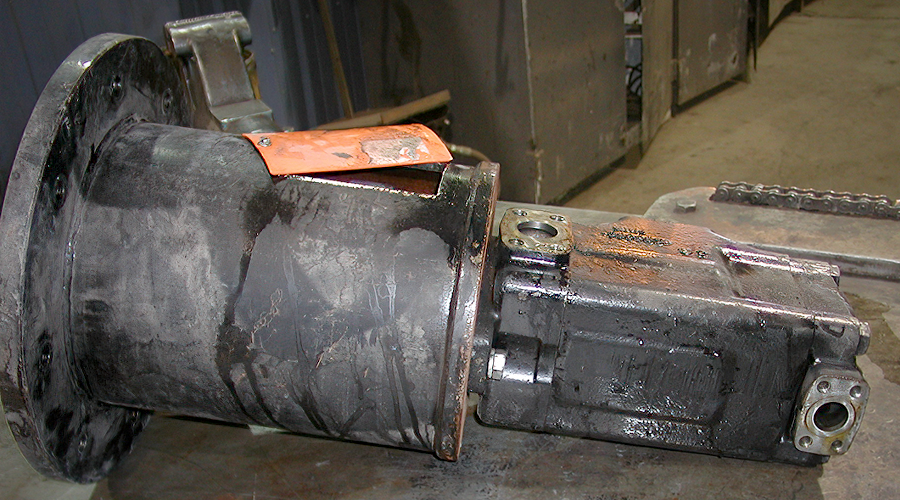

One of the primary causes of hydraulic system failure is inadequate maintenance. Hydraulic systems are complex and require regular maintenance to ensure their proper operation. Over time, hydraulic fluids can become contaminated, components can wear out or break, leaks can occur. If these issues are not addressed promptly, they will lead to significant system damage and ultimately result in failure and the resultant unscheduled downtime.

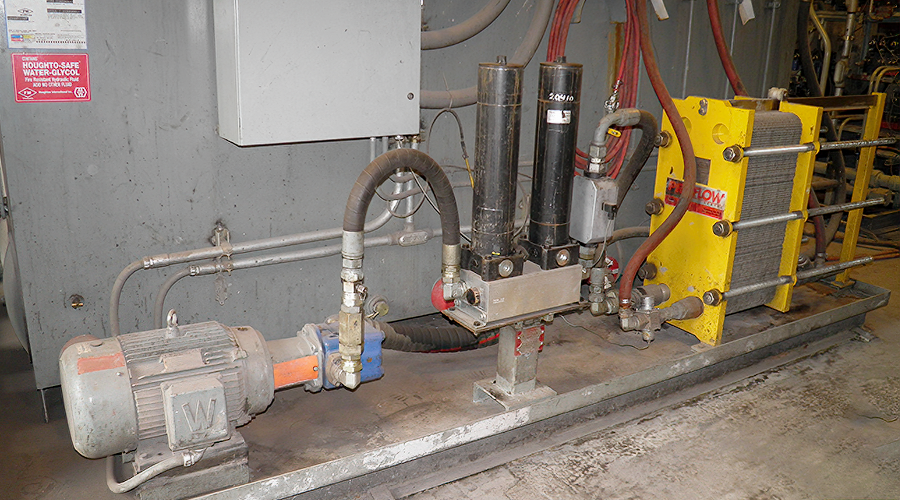

Proper maintenance is at the heart of preventing hydraulic system failure. This includes regularly changing the hydraulic fluid, inspecting the system for leaks or other issues, and replacing worn or damaged components. Additionally, it is crucial to use the correct hydraulic fluid for the application and to ensure that the fluid is clean and free of contaminants. Filters and other components can be used to remove contaminants from the fluid, but they too must be maintained and replaced regularly to be effective.

Contaminated oil is the cause of more than 75% of all hydraulic system failure. Hydraulic fluids can become contaminated with dirt, debris, and other particles that can damage system components. Contamination occurs during the manufacturing process, during installation, or during operation. Even small amounts of contamination can cause significant damage to the system over time. Proper contamination control is central to preventing hydraulic system failure. This involves using the right type of fluid for the application, and ensuring that it is clean and free of contaminants.

Temperature control is another vital factor in preventing hydraulic system failure. Hydraulic fluids are sensitive to temperature changes, and if the fluid becomes too hot, or too cold, it can cause damage. For example, if the fluid becomes too hot, it can break down and lose its lubricating properties, causing amplified wear and tear on system components. On the other hand, if the fluid becomes too cold, viscosity increases and the fluid becomes less effective at transferring power. This causes sluggish performance and often, system failure.

Proper temperature control is necessary to prevent hydraulic system failure. This encompasses using the right type of hydraulic fluid for the application, monitoring the temperature of the fluid, and installing a correctly engineered system in the first place. Hydraulic training is key to understanding the appropriate temperature range for a particular system as well as how to monitor and control the temperature of the fluid.

Improper use, and the abuse, of hydraulic systems can also cause system failure. Overloading hydraulic machinery, or using it in a way that it was not intended, can cause significant damage to the system’s components. Additionally, all hydraulic systems experience wear over time, and components will need to be replaced periodically to ensure proper operation.

Finally, poor installation can also contribute to system failure. Hydraulic systems must be installed correctly to ensure intended operation. Improper installation can result in leaks, component failure, and other issues that can cause system failure.

In conclusion, hydraulic system failure can be caused by a variety of factors, including inadequate maintenance, contamination, temperature control issues, improper system use or abuse, and deficient installation. Preventing hydraulic system failure requires maintenance, contamination control, temperature control, system design and installation. A well-educated maintenance staff makes the difference between years of trouble-free operation and years of increasing downtime. This is why we at Hydraulic Training NW, LLC. feel that hydraulic training is so important. We can help.

Inadequate Maintenance is the First Step to Inadequate Performance.