“The fluid is the lifeblood of any hydraulic system, and a sound hydraulic fluid strategy is integral to optimizing system performance and longevity.”

For more details, please contact us:

Phone: (971) 264-0400

When it comes to the performance and longevity of hydraulic systems, few things are more important than the hydraulic fluid itself. The design, selection, and maintenance of hydraulic fluid significantly impacts a system’s efficiency, durability, and safety. This article, aimed at those seeking hydraulic training, will delve into the core principles of hydraulic fluid design strategies, ensuring that you have the knowledge necessary to optimize your hydraulic system’s performance.

The Role of Hydraulic Fluid

Before diving into design strategies, it’s important to understand the pivotal role hydraulic fluid plays in a hydraulic system. Hydraulic fluid is more than just a medium for power transmission. It also lubricates the system, reduces friction, cools the components, and removes contaminants. Thus, proper design and selection of hydraulic fluid is crucial for maximizing system efficiency and lifespan.

Understanding the System Requirements

The first step in designing a hydraulic fluid strategy is to understand the specific requirements of your hydraulic system. The nature of your operation, the type of hydraulic pump used, the operating environment, and the system’s pressure and temperature ranges are all vital factors that should guide your hydraulic fluid strategy.

Hydraulic training emphasizes the need to understand these variables. They will not only guide the type of hydraulic fluid used but also influence other design strategies such as filtration, contamination control, and fluid maintenance schedules.

Choosing the Right Hydraulic Fluid

There are several types of hydraulic fluids available in the market, including mineral oil, synthetic fluids, water-based fluids, and biodegradable fluids. Each type has its own strengths and weaknesses, and the choice depends on the specific application.

Mineral oil-based fluids are the most common due to their good lubrication properties and cost-effectiveness. However, they might not perform well under extreme temperatures or in environmentally sensitive applications.

Synthetic fluids are designed to perform under extreme conditions and have superior thermal stability, but they are more expensive.

Water-based fluids are excellent for fire-resistance but lack good lubrication properties.

Biodegradable fluids, made from natural esters, are suitable for environmentally sensitive applications.

In hydraulic training, it is emphasized that choosing the right hydraulic fluid requires a thorough understanding of the system’s operational requirements and the fluid’s properties.

Hydraulic Fluid Filtration

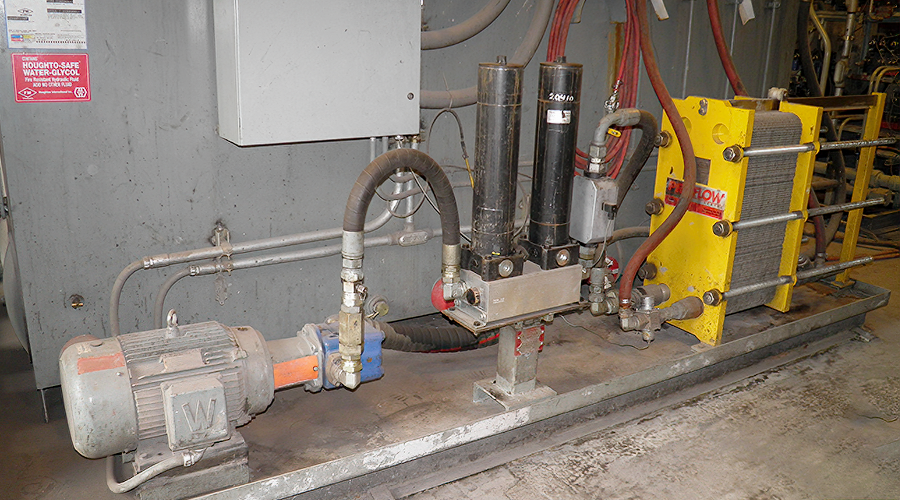

A key aspect of hydraulic fluid design strategy is ensuring that the fluid remains clean and free from contaminants. Contamination can cause various problems, ranging from increased wear and tear to system failure.

Hydraulic fluid filtration is a critical component of a sound hydraulic fluid design strategy. Filters should be strategically placed in the system, such as at the fluid’s entry point (suction filter), in the pressure line (pressure filter), and before the fluid returns to the reservoir (return line filter). The filter’s design and selection, which are integral to hydraulic training, depend on factors such as the system’s pressure, flow rate, contamination level, and the required cleanliness level.

ISO Cleanliness Codes and Beta Ratios

Designing an effective filtration strategy requires a good understanding of the ISO Cleanliness Code and Beta Ratios, which represent the cleanliness level of hydraulic fluid and the efficiency of the filters, respectively.

ISO Cleanliness Code (ISO 4406) indicates the number of particles of specific sizes per unit-volume of fluid; lower numbers represent cleaner fluid. Understanding this code helps target the appropriate filtration system to achieve the desired cleanliness level.

The Beta Ratio represents the ability of a filter to remove a certain size of contaminant from the fluid. For instance, a Beta Ratio of 200 at 10 microns means that for every 200 particles of 10 microns or larger that enter the filter, only one particle of the same size or larger will pass through. Understanding the Beta Ratio helps in selecting the most efficient filter for your system.

Fluid Maintenance and Monitoring

Regular fluid maintenance is a key part of a robust hydraulic fluid design strategy. This includes monitoring the fluid’s physical and chemical properties regularly, topping up the fluid to the appropriate level, and changing the fluid as per the manufacturer’s recommendations.

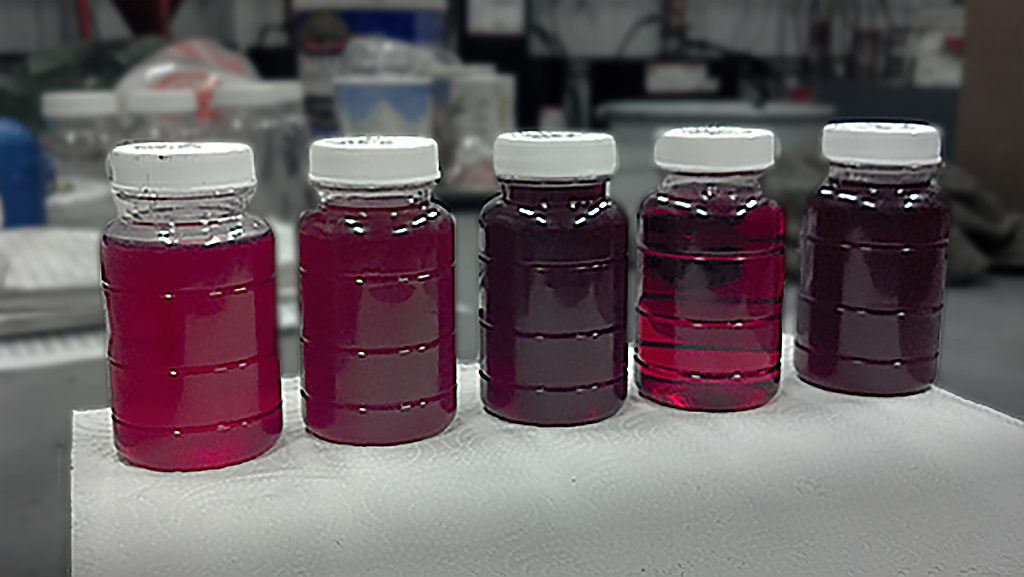

Hydraulic training emphasizes the importance of regular fluid analysis. It involves checking the fluid for properties such as viscosity, acidity (pH), water content, and contamination level. Regular fluid analysis can provide early indications of potential problems, such as excessive wear, fluid degradation, or contamination, allowing you to take corrective action promptly.

In Conclusion

The fluid is the lifeblood of any hydraulic system, and a sound hydraulic fluid strategy is integral to optimizing system performance and longevity. From understanding the system requirements to selecting the right fluid, designing an efficient filtration system, and ensuring regular fluid maintenance, all play a crucial role in the overall strategy. Whether you are a beginner looking for hydraulic training or an experienced professional seeking to enhance your knowledge, understanding these hydraulic fluid design strategies will help you make informed decisions and ensure the smooth and efficient operation of your hydraulic systems. With proper training and understanding, you can ensure that your hydraulic systems continue to function effectively, efficiently, and safely.

Hydraulic fluid is more than just a medium for power transmission.