“Higher cleanliness levels (lower numerical codes) reduce the risk of system failure, improve component life, and enhance system efficiency.”

For more details, please contact us:

Phone: (971) 264-0400

When it comes to operating hydraulic systems effectively and efficiently, the importance of hydraulic fluid cannot be overstated. Hydraulic fluid plays a crucial role in transferring power, protecting components, and improving the system’s overall lifespan. It is essential to understand the key parameters used to gauge hydraulic fluid’s condition and performance – the Beta Ratio, Micron Rating, and ISO Cleanliness Code. This article will delve into these ratings, explaining how they are rated, their scientific properties, and their significance.

Beta Ratio

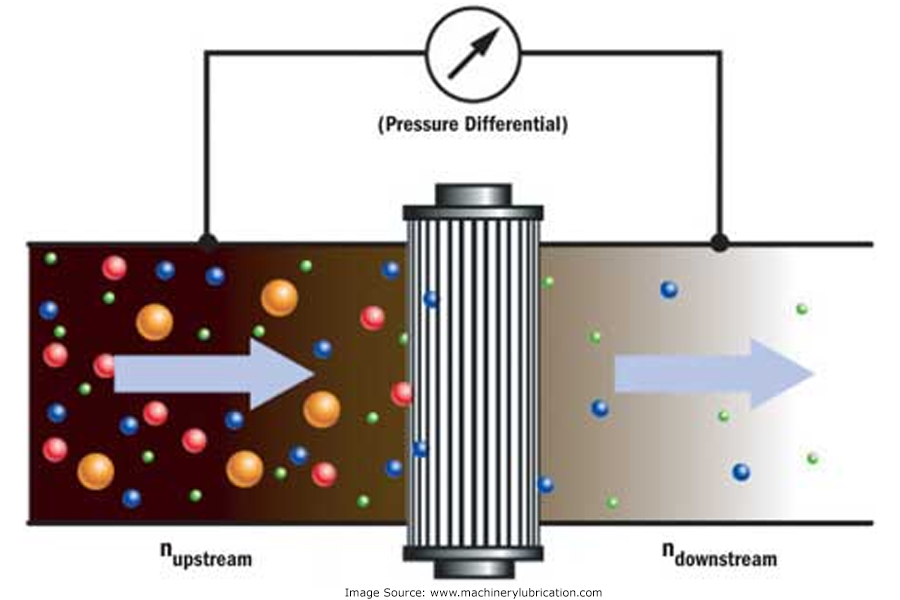

The Beta Ratio, or β, is a commonly used parameter in the field of fluid power to quantify the filtration efficiency of a hydraulic filter. Essentially, the Beta Ratio indicates the filter’s ability to remove a specific size of contaminant from the hydraulic fluid.

The Beta Ratio is calculated as:

βx = Number of Particles ≥ x (µm) Upstream / Number of Particles ≥ x (µm) Downstream

where ‘x’ is the size of the particle in micrometers (µm)

For instance, if a filter has a Beta Ratio (β10) of 100, it means that for every 100 particles of 10 micrometers or larger entering the filter, only one particle of the same size or larger is allowed to pass through.

The Beta Ratio, therefore, offers a quantitative and comparable measure of filter efficiency. It provides manufacturers and users with a standardized benchmark to assess the performance of different filters, ensuring that the right filter is used for a given application.

Micron Rating

The Micron Rating is another critical concept when discussing hydraulic filter ratings. It describes the nominal pore size of a filter, representing the smallest particle size that the filter is designed to capture. This rating is typically expressed in micrometers (µm).

This Micron Rating can be of two types: nominal and absolute. A nominal micron rating signifies the filter’s ability to capture a certain percentage (usually 50% or more) of particles of a specific size. On the other hand, an absolute micron rating indicates the maximum particle size that a filter will allow to pass.

For example, a filter with a nominal micron rating of 10 µm will remove approximately 50% or more of particles that are 10 µm in size or larger. In contrast, a filter with an absolute micron rating of 10 µm will remove virtually all particles larger than 10 µm.

The micron rating is integral to optimizing filter selection and maintaining hydraulic fluid cleanliness, as it directly affects the efficiency of contaminant removal. However, it should not be the only factor considered. Other filter properties, such as filter media, design, and construction, significantly influence overall filtration performance.

ISO Cleanliness Codes

The International Organization for Standardization (ISO) has established a standard method to quantify the level of contamination in hydraulic fluids, known as ISO Cleanliness Code (ISO 4406). This system provides a quick, simple way to express fluid cleanliness levels based on the number of particles per unit volume of fluid at specific micron sizes.

The ISO 4406 Cleanliness Code consists of three numbers (e.g., 18/16/13), which indicate the number of particles of sizes ≥4 µm, ≥6 µm, and ≥14 µm per milliliter of fluid, respectively. Each number corresponds to a range on a logarithmic scale. For example, the code of ’18’ represents a range of 1300 to 2500 particles of the specified size per milliliter.

Understanding and maintaining the appropriate ISO cleanliness level is vital for the performance and longevity of hydraulic systems. Higher cleanliness levels (lower numerical codes) reduce the risk of system failure, improve component life, and enhance system efficiency.

The Science Behind These Concepts

The principles governing these concepts are derived from fluid dynamics and particle physics. Contaminant particles in hydraulic fluid can cause a multitude of problems, including increased wear, blockages, and decreased efficiency. Therefore, the ability to control and quantify these particles is essential.

Both the Beta Ratio and Micron Rating are rooted in the science of filtration. The Beta Ratio is based on the statistical particle count of contaminants before and after passing through a filter, leveraging the principles of fluid flow and particle capture. In contrast, the micron rating, derived from sieve analysis principles, reflects the physical barrier function of the filter, its pore size distribution, and its ability to trap particles of a certain size.

The ISO Cleanliness Code, on the other hand, relates to the science of particle distribution and counting. It utilizes light-blocking particle counters or automatic microscope particle counters to provide a statistical measure of the particle concentration in a fluid, categorized by size.

In conclusion, understanding hydraulic fluid ratings – the Beta Ratio, Micron Rating, and ISO Cleanliness Code – is paramount for optimal hydraulic system operation. These measures help maintain fluid cleanliness, protect the system components, and enhance overall system performance and longevity. By understanding the science behind these concepts, manufacturers and users alike can make informed decisions, ensuring the reliability and efficiency of their hydraulic systems.

Contaminated hydraulic fluid devastates critical components.